Driving the Future of Sustainable Packaging

High-performance Technology

We use cutting-edge extrusion technology to deliver superior stretch, load containment and puncture resistance

Recycled plastic

We use a percentage of PCR in our

Stretch Film (Post-Consumer Recycled Content)

Our solutions were engineered to reduce your plastic usage without compromising on quality or performance.

ABOUT US

We focus on high-tech and renewable resources to ensure a better tomorrow.

Epsilon is a leader company established in Guatemala whose main focus is the conversion, extrusion, and manufacturing of films. Our commitment is to provide high-quality products and superior customer satisfaction with innovation and continuous development.

Epsilon belongs to the Constela Group, which was founded more than 30 years ago providing materials, fabrics, accessories for clothing, and packaging solutions.

WHAT WE CARE

Sustainability and Innovation

We create sustainable packaging solutions focusing on high-tech and renewable resources to ensure a better tomorrow.

Sustainability

![]() Nowadays, sustainability in packaging has become a crucial aspect for several industries. We offer a solution to companies to protect their products, but in an efficient and environmentally responsible manner with the optimization of stretch film, a key packaging material that, thanks to innovation, can significantly reduce environmental impact without compromising quality or functionality.

Nowadays, sustainability in packaging has become a crucial aspect for several industries. We offer a solution to companies to protect their products, but in an efficient and environmentally responsible manner with the optimization of stretch film, a key packaging material that, thanks to innovation, can significantly reduce environmental impact without compromising quality or functionality.

Optimization

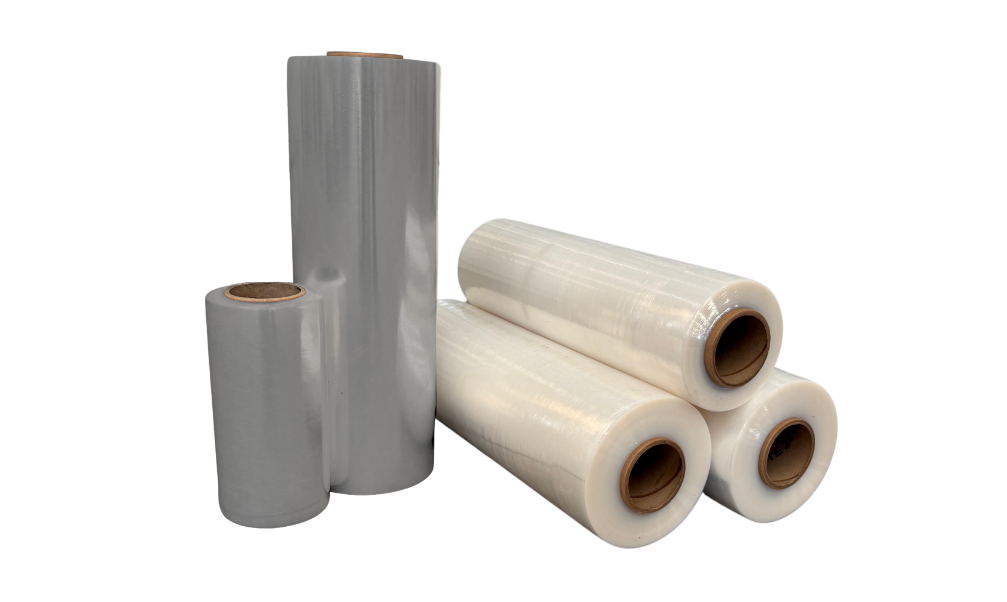

![]() Stretch film, traditionally used to wrap products during transport, is now being optimized to reduce both material use and the plastic waste generated.

Stretch film, traditionally used to wrap products during transport, is now being optimized to reduce both material use and the plastic waste generated.

Efficiency

![]() We provide significant economic benefits by reducing operating costs and improving logistics efficiency, while making a tangible impact on the planet minimizing environmental harm.

We provide significant economic benefits by reducing operating costs and improving logistics efficiency, while making a tangible impact on the planet minimizing environmental harm.

USES

When to use Stretch Film?

By tightly wrapping items, stretch film can help prevent theft and manipulation of goods.

For inventory management, sale, or transit, loose goods can be covertly banded together using a soft hand or bundling/banding wraps.

Compared to other wrap materials, stretch films tend to be ligther and more economical.

Stretch film is used to protect items from dust, dirt, moisture, and physical damage during storage.

When moving big items, stretch wrapping provides the optimal level of safety and protection.

By protecting items from damaging environmental conditions, stretch film can help extend the shelf life of certain items.

RESOURCES

How to Choose the Right Stretch Film for Your Operation

Type of load and protection needed

Are you transporting light, uniform loads or heavy, irregular ones? This affects the gauge, stretch level, and tear resistance your operation requires. For example, our Ultra High Performance Stretch Film offers strong load containment with less material—ideal for demanding loads.

Type of application: manual or automatic

For low-volume operations, Manual Stretch Film is a cost-effective and practical solution. On the other hand, if you work with high-speed wrapping machines, our Automatic and Pre-Stretched Film optimizes application, reduces waste, and improves efficiency.

Environmental conditions and pallet type

Factors like temperature, humidity, or transport distances require film with specific properties. At Epsilon, we offer formulations tailored to demanding industrial environments, ensuring reliable performance under any condition.

BENEFITS

Stretch film offers multiple benefits:

By reducing plastic waste, companies can improve their sustainability profile and comply with increasingly strict regulations.

The adoption of innovative technologies and solutions in packaging becomes essential to ensure its competitiveness in the global market.

These advances not only reduce waste and costs, but also strengthen the reputation of brands committed to the environment. Without a doubt, the future of sustainable packaging is marked by innovation.

2024 | All rights reserved © | epsilonpkg.com